Safety Information

Specialized Lighting Concepts (SLC) products are designed with specific protection features for an optimal consumer safe experience.

Please read this important safety information to ensure your LED installation is sustainable long term. Failure to do any of the

following conditions will void warranty and could cause product failure as a result.

- All LED products must remain fully accessible at all times in order to be retrieved for repair or maintenance.

- Only use SLC certified power supplies, certified power supplies protect you and your LED installation

- LED rigid board modules are not to be mechanically stressed by bending or shaping beyond the straight format as supplied. Placing pressure on the actual LED is to be avoided at all times.

- Use qualified persons to install LED products. Specific electrical safety standards need to be follow in accordance with New Zealand regulations.

- Adhere to correct electrical polarity, if correct polarity is not observed damage may be caused to the LED module.

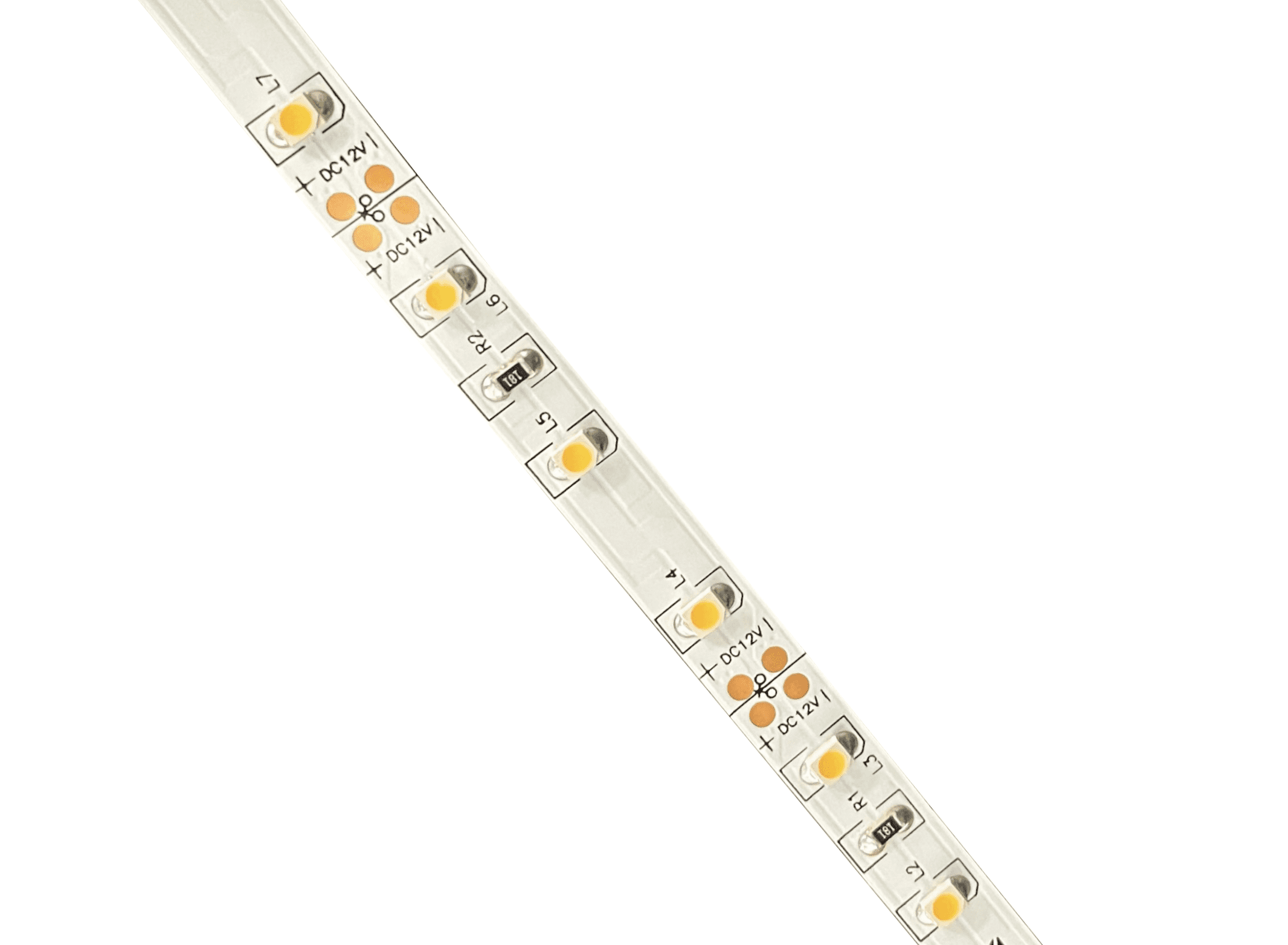

- Only cut or divide the LED modules on the specified cutting markings indicated on the LED module, normally marked by a line or scissor symbol.

- Touching metallic parts can cause electrostatic discharge, use ESD precautions.

- Certain modules do not have IP properties meaning they do not offer protection against corrosion, moisture, dust and water damage, if you are unsure check the IP rating on the SLC product specification sheet or consult SLC for further information. Corrosion as a warranty claim will not be accepted for non IP rated products. It is the installers responsibility to ensure the specified product is either coated or protected from moisture, condensation and other corrosive elements.

- When soldering is required in the installation process, this soldering must be protected against corrosion, and this includes all metal parts of the module being lacquered sufficiently.

- LED dimming can only be achieved with a certified low voltage pulse width modulation (PWM) or analogue (0-10V) dimmer. Check with SLC before installing any dimming system.

- Your LED installation must be well ventilated in order for the LED modules and accessories to survive long term. Excessive heat in the LED cavity will cause a reduction in the LEDs life or product failure.

- High pressure hoses must not be used to clean IP rated products.

- Each LED product will have specific power requirements and unique attributes. In order to get the best out of your LED product and enable the system to function correctly, you will need to carefully read and follow individual product specifications for each product.

- Products must be free of dust, dirt and obstructions to enable the light to emit onto the desired area in a uniform manner.

- Products are not suitable when being exposed to the marine environment unless the product specification is clearly marked “product is suitable for marine environment”. All special instructions must be followed and all care taken to ensure common sense is practised.

- led product that is used in conjunction with other light fittings in the same cavity should be kept in separate compartments ot prevent colour mixing between light fittings and excessive heat generated by the non-LED product.

- As with all LED lamps and fittings, light depreciation should be expected throughout the lifetime of the product.

- LED products may differ slightly in Kelvin degrees (LED colour) between bathces. SLC will ensure individual orders have consistent Kelvin levels. Please contact us before ordering if colour matching between orders is required.

- Under no circumstances will SLC be liable for any charges relating to the removal, re-installation or freight in regards to product installations except where agreed over page.

- All warranty claims must be sent to SLC at the resellers expense unless prior arrangements have been made with SLC and written approval is provided by SLC of any arrangements. Our product warranty is strictly on a “return to base” basis.

- Quality sealant must be used if placed in an outdoor environment. This sealant must be rated at least for the lifetime of the product.

- Products that are installed without following correct installation procedures detailed in the product instruction manual or specification sheets will not be accepted as warranty. If the installer does not receive a copy of these it is the installers responsibility to obtain this before installing the product.

- LED products used in enclosed environments with little or no ventilation are not permitted.

- LED products used are not to be installed in direct sunlight unless the product is rated as UV resistant in the product specification sheet provided by SLC.

- If an on-site visit is required to assess problems relating to SLC products and it is found to be caused by incorrect installation then a call out charge will apply.

.png)

.png)

.png)

.png)

.png)

.png)

.png)